Inside the DOE's Autonomous Lab for Materials Discovery

A lab tour and conversation with David Milsted, Lawrence Berkeley National Laboratory

“We can have people constantly inserting new experiments, and the lab’s going to manage everything, calling us from time to time just to clean some things” – David Milsted, Lab Systems Engineer

Imagine you’re a VP at a top EV battery manufacturer. Your biggest clients – Mercedes, BMW, Ford, Rivian – are sounding the alarm: your lithium-ion batteries are prone to dangerous flare-ups. Even when they function safely, they degrade too fast, stoking range anxiety and dragging down the resale value of their cars.

The fix seems obvious: get back in the lab and reformulate your battery’s chemistry. But where do you even begin?

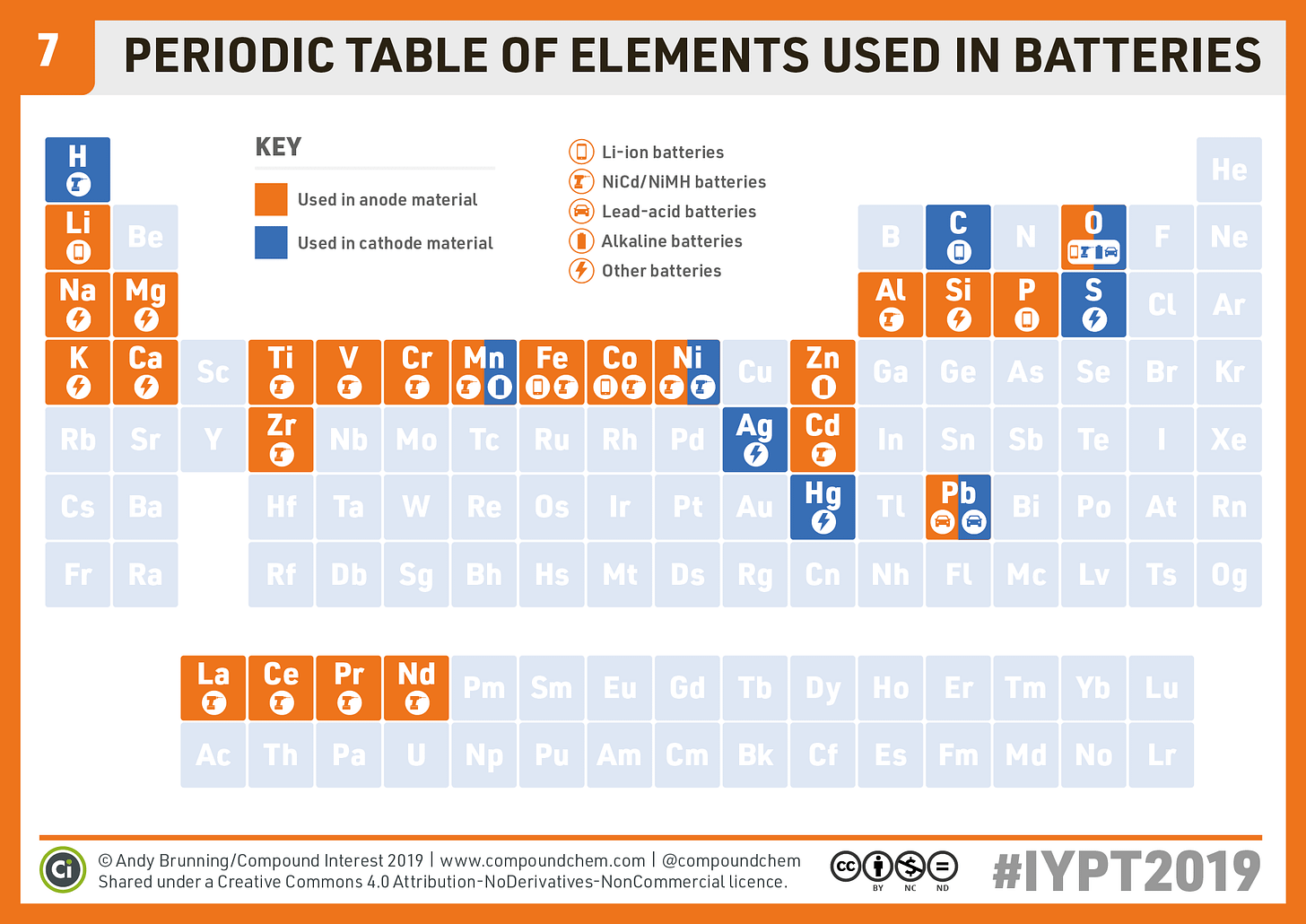

There are 90-some naturally occurring elements on the periodic table, and choosing just six from a pool of 30 viable ones gives you over half a million possible combinations. Which ones definitely won’t work? Which ones might? And how do you accelerate the trial-and-error process of testing new materials?

That’s why I was so excited to visit the “A-Lab” at Lawrence Berkeley National Labs, an autonomous facility for accelerating materials discovery managed for the US Department of Energy. With a mix of AI and robotics, the A-Lab is making it possible to explore large chemical spaces faster than ever, with an initial focus on developing safer, better batteries.

During my tour and conversation with David Milsted, a postdoctoral researcher at the lab, we explored:

How automated labs predict, synthesize, and test materials

The orchestration of autonomous experiments through the A-Lab OS

The future of materials characterization using automated microscopy

Behind-the-scenes insights into running complex autonomous lab systems (e.g. robotic dispensers, speed mixers, and automated furnaces)

David’s personal journey into lab automation, starting with his wood science studies in Brazil 🇧🇷

Watch or Listen Now

If you’re excited by automation, materials science, and seeing how labs can drive innovative research around the clock, join us for this conversation and lab tour.

Also available on:

Spotify: https://spoti.fi/42Uvv5J

Apple Podcasts: https://apple.co/40sQCu9

Additional Show Notes

Episode Links:

David's LinkedIn https://www.linkedin.com/in/dmilsted/

Lawrence Berkeley National Lab https://www.lbl.gov/

A-Lab https://newscenter.lbl.gov/2023/04/17/meet-the-autonomous-lab-of-the-future/

Ceder Group https://ceder.berkeley.edu/research-areas/autonomous-experimentation-for-accelerated-materials-discovery/

UC Berkeley https://www.berkeley.edu/

Mississippi State University https://www.bioproducts.msstate.edu/

Wood Science https://en.wikipedia.org/wiki/Wood_science

Episode Chapters:

00:00 - Preview & Introduction

04:37 - LBNL Fun Facts

05:40 - David’s Journey Into Lab Automation (Wood Science, Automation Engineering)

10:26 - Why Wood Science

14:54 - Journey From Brazil To LBNL

25:50 - Material Discovery Process Steps

29:37 - Predicting Materials Properties

35:07 - Synthesizing Materials With Automation

43:21 - Testing Novel Materials

44:58 - Orchestrating Automated Labs (A-Lab OS)

49:14 - Shifting From Independent to Team-Based Projects

53:28 - University-Government Lab Structure

57:41 - What Inspired A Lab’s Vision

01:02:40 - Growth in Autonomous Lab Investment

01:05:34 - Future of Characterization Via Microscopy

01:10:22 - A Lab Tour (Core Components)

01:15:44 - Vendor Support: Mitsubishi, Labman, MTI, etc

01:18:58 - Managing Input Inventory For Runs

01:20:12 - Furnace Deep Dive

01:24:06 - Parallel Processing

01:25:43 - Vendor Automation Out of the Box; Importance of Societal Awareness